Brake pads are designed to wear down. That’s their job. Think of the friction material on your pads like the sole of a running shoe—every time you hit the brakes, a tiny bit wears away to create the friction that stops your car. Understanding this process isn't just for mechanics; it’s a critical piece of knowledge for every driver's safety and budget.

Why Brake Pads Wear Is a Critical Safety Check

Picture your car moving down the highway. It’s carrying a massive amount of forward momentum, or kinetic energy. When you need to stop, all that energy has to go somewhere. Your brake pads are the unsung heroes here, converting that powerful forward motion into heat through friction. They are literally designed to sacrifice themselves in this process.

This sacrificial design is exactly why keeping an eye on brake pads wear is so important. As that friction material gets thinner, its ability to manage heat and generate stopping power drops off. Letting it go unchecked doesn't just lead to sloppy braking; it can lead to total brake failure, turning a normal stop into a genuinely dangerous situation.

From Prevention to Performance

Staying ahead of brake wear is the key to both safety and saving money. Once the pads wear out completely, the metal backing plate starts grinding directly against the brake rotor. This metal-on-metal contact creates a horrifying noise and chews up the rotors in no time, turning a straightforward maintenance job into a much bigger and more expensive repair.

A routine brake pad replacement costs a fraction of what it takes to replace both pads and a set of damaged rotors. Regular inspections are a small investment to prevent those much bigger, costlier problems down the road.

Here in Dallas, the mix of highway speeds and constant stop-and-go traffic is particularly tough on brakes. We often see local drivers’ pads wear out 10-15% quicker than in more rural areas, which really highlights why you should have them checked during every oil change or state inspection.

A Quick Guide to Brake Pad Health

To make things simple, here’s a quick reference table that breaks down the key signs and guidelines for your brake pads. Knowing what to listen and look for is half the battle. You can easily incorporate these checks into your routine—our comprehensive vehicle inspection checklist is a great way to stay on top of all your car's essential maintenance tasks.

Brake Pad Wear Quick Reference Guide

This table gives you an at-a-glance summary of what to look for and what it means for your vehicle's safety.

| Symptom or Guideline | What It Means | Recommended Action |

|---|---|---|

| High-Pitched Squeal | The built-in wear indicator is touching the rotor. | Schedule a brake inspection soon. |

| Grinding Noise | The pads are gone; metal is grinding on metal. | Stop driving immediately and get professional service. |

| 3mm Pad Thickness | The friction material is at the minimum safe level. | Plan for immediate brake pad replacement. |

| 12-Month Check | Recommended interval for a pro brake system inspection. | Schedule an inspection with your next oil change. |

Keeping this guide in mind will help you catch brake issues early, ensuring you and your passengers stay safe on the road.

Learning to Spot the Telltale Signs of Wear

Your car is a pretty complex piece of machinery, but it has some surprisingly simple ways of telling you something's wrong. When it comes to your brake pads, your vehicle will give you clear sensory clues—you just have to know what to listen for and what to feel. Ignoring these signals is like hitting snooze on a smoke alarm; the problem only gets bigger and more dangerous.

These aren't just random quirks, either. The warnings are engineered right into the system to grab your attention long before wear and tear becomes a critical safety issue. Once you understand the "why" behind each sound and sensation, you can catch problems early and handle them with confidence.

The Sounds Your Brakes Make

More often than not, the first hint of worn brake pads is something you'll hear. The noises can range from a subtle, high-pitched annoyance to a sound you absolutely can't ignore. Each one tells a different story about what's happening with your brakes.

High-Pitched Squealing: This is usually the first red flag. Most brake pads have a small metal tab built into them called a wear indicator. As the friction material on the pad wears down to a certain point, this little tab starts scraping against the brake rotor, creating that unmistakable high-pitched squeal when you brake. Think of it as your car's built-in alarm system, letting you know it's time to book an inspection.

Deep, Harsh Grinding: If you hear a loud, metallic grinding or a deep growling noise, the situation has become urgent. This sound means the friction material on the pads is completely gone. What you're hearing is the metal backing plate of the brake pad grinding directly against the metal rotor. This not only tanks your ability to stop safely but also actively destroys your rotors, turning a simple maintenance job into a much more expensive, multi-part replacement.

If you hear a grinding noise, it is critical to stop driving the vehicle as soon as it is safe to do so. Continuing to drive can cause catastrophic brake failure and extensive damage to other components of your braking system.

Sensations You Can Feel

Beyond what you can hear, you can often feel the effects of brake pad wear right through the brake pedal and even the steering wheel. These physical symptoms are direct clues that something isn't right inside the braking system.

A vibrating or pulsating brake pedal is a classic symptom. This often points to warped brake rotors, a problem that can develop when thin, worn-out pads can't properly absorb the intense heat from braking. The constant stop-and-go traffic on Dallas highways like I-35 can easily lead to this kind of overheating. If this sounds familiar, you can learn more about why your front end shakes when braking in our detailed guide.

Changes in Brake Performance

Finally, the most direct evidence of worn brake pads is a noticeable drop in how well your vehicle actually stops. These changes can happen so gradually that they're easy to miss until they become a real problem.

Pay close attention to these performance red flags:

Longer Stopping Distances: If you find yourself needing more and more road to come to a full stop, your pads are likely on their way out. The reduced friction material just can't create the force needed to stop your car as quickly as it should.

A "Spongy" or Soft Brake Pedal: Does the brake pedal feel less responsive when you press it? Maybe it sinks closer to the floor than it used to. This could be a sign of worn pads, or it could point to a more serious issue with your brake fluid or the hydraulic system.

Vehicle Pulling to One Side: If your car veers to the left or right when you hit the brakes, it might mean the pads are wearing unevenly. This can be caused by problems like a stuck caliper, creating an imbalance in the braking force from one wheel to the other.

Staying tuned in to these sounds, feelings, and performance shifts is the best way to get ahead of brake problems. Catching these signs early means you can get it fixed before it ever puts your safety on the line.

How to Perform a Basic Visual Brake Inspection

You don’t need a full mechanic’s toolkit to get a feel for your brake health. A simple visual check is a powerful first step, letting you spot potential brake pad wear long before it turns into a serious problem. With just a few minutes and a good look, you can stay ahead of the game.

First thing’s first: safety. Always park your car on a flat, level surface. Make sure the engine is off and the parking brake is on. And never, ever try to inspect your brakes right after a drive—those parts get incredibly hot.

Peeking Through the Wheel

The easiest way to check your pads is by looking right through the spokes of your wheels. You might need a flashlight to get a clear view, especially if you have complex rim designs. Your target is the brake caliper, which is the big clamp that squeezes the shiny metal disc (the rotor).

Tucked inside that caliper, you’ll see the brake pad pressed against the rotor. You’re looking for two parts: the thin metal backing plate and the thicker friction material stuck to it. That friction material does all the heavy lifting, and its thickness is what you need to check.

Think of it like checking the tread on your tires. Worn-out tread means less grip on the road, and a thin layer of brake friction material means less stopping power. It's the same principle.

What Is a Safe Pad Thickness?

So, what are you looking for, exactly? A brand-new brake pad has about 10-12 millimeters of friction material. The industry-wide rule of thumb is that the minimum safe thickness is around 3-4 millimeters.

To put that in perspective, that’s about the thickness of two dimes stacked together. If your pad material looks that thin—or even thinner—it’s time to book a replacement right away. Anything less than that drastically reduces your ability to stop safely, especially when you need it most.

While you're down there, check for uneven wear. Does the pad look a lot thinner on one side of the rotor compared to the other? That’s a red flag. It can point to bigger problems, like a sticking brake caliper that isn't applying pressure correctly.

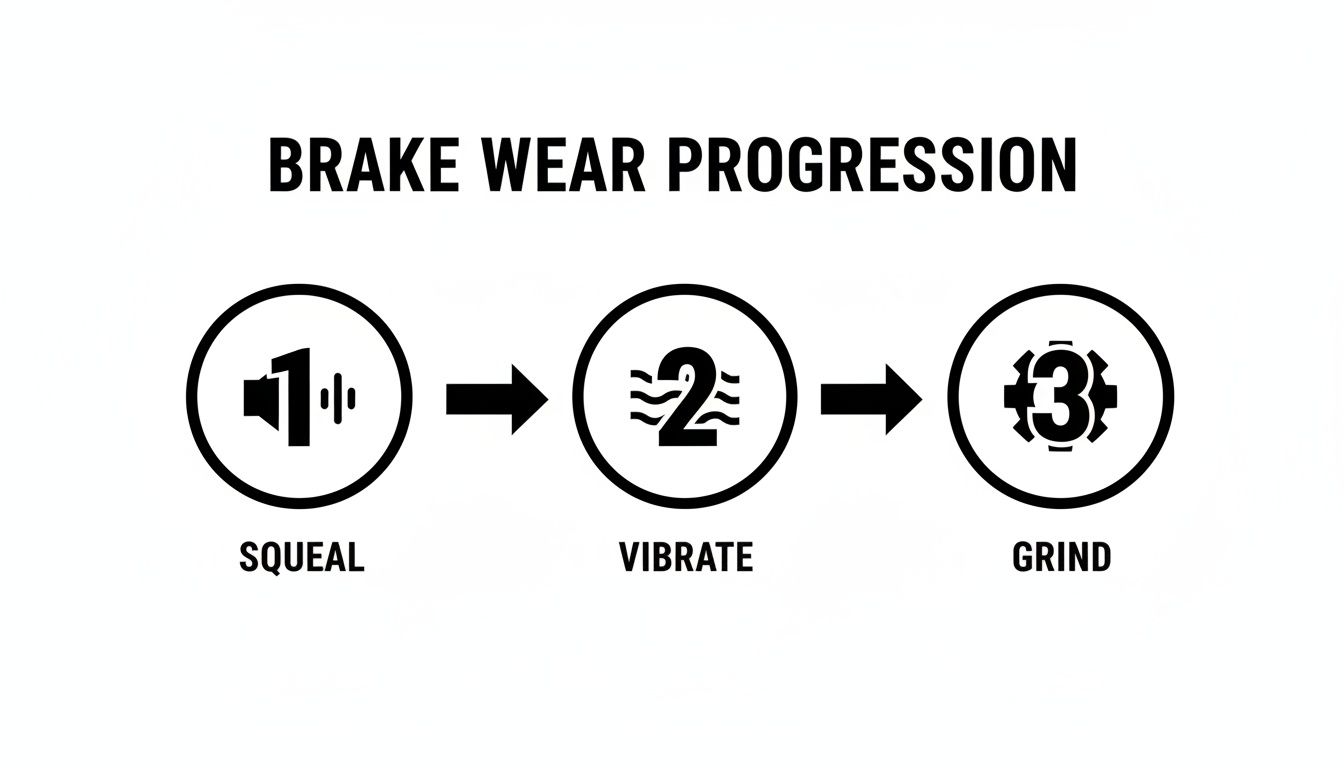

This next image perfectly shows how brake wear progresses, from the first sound you hear to a critical failure.

As you can see, a simple squeal is your early warning. Vibration means the problem is getting worse. And a grinding noise signals severe, metal-on-metal damage that needs immediate attention.

Understanding Modern Wear Indicators

Luckily, modern cars have built-in alarm systems to warn you before the wear gets dangerous. These brake pad wear indicators have been a real game-changer for safety, designed to grab your attention before the friction material is gone for good.

There are a couple of common types you'll find:

- Acoustic Indicators: This is that little metal clip we talked about earlier that makes the high-pitched squeal. It’s a beautifully simple—and effective—mechanical warning.

- Electronic Sensors: Many newer cars have electronic sensors built right into the brake pad material. Once the pad wears down to a specific point, the sensor touches the rotor, which completes an electrical circuit and lights up a warning on your dashboard.

The evolution of these indicators is a massive leap forward for road safety. They’re designed to alert drivers when pads are dangerously thin, usually around 2-3mm, helping prevent brake-related incidents which contribute to 20% of U.S. crashes. What started in luxury European cars in the 1980s is now standard in about 70% of passenger vehicles across the U.S. and EU. You can see more data by reading the full report on brake pad wear indicators.

By combining a quick visual check with an ear for these built-in alerts, you can stay confidently in control of your brake maintenance.

Choosing Between DIY Repair and Professional Service

So, you’ve discovered your brake pads are worn. Now you're at a fork in the road: do you roll up your sleeves and tackle the job yourself, or hand the keys over to a pro? This decision isn't just about saving a few bucks; it's a careful balance of your time, expertise, and comfort level with one of your car’s most critical safety systems.

Making the right call starts with being honest about what a brake job really involves. It’s often painted as a simple "unbolt and replace" task, but the reality can be far more complicated. The chance of running into a seized bolt, needing a special tool you don't have, and the absolute importance of getting it right means a DIY approach isn't for everyone.

The Realities of a DIY Brake Job

For the hands-on car owner, swapping out your own brake pads can be a rewarding, cost-saving project. The biggest draw is, of course, avoiding labor costs. But it's crucial to go into it with your eyes wide open, knowing what’s required and what can go wrong.

A successful DIY brake job comes down to having the right gear and knowledge. You'll need more than a basic wrench set from the hardware store. The essential tool list usually includes:

- A sturdy jack and jack stands to safely lift and secure your vehicle.

- A lug wrench to get the wheels off.

- A C-clamp or piston compression tool to push back the brake caliper piston.

- A torque wrench to tighten bolts to the manufacturer's exact specs—this is non-negotiable.

- Brake cleaner and high-temperature grease for proper cleaning and lubrication.

Beyond the tools, you need the patience to handle common frustrations. Bolts can be rusted solid, caliper slide pins can get stuck, and bleeding the brake lines—if it becomes necessary—requires precision to avoid getting air in the system, which can be dangerous.

The Case for Professional Service

Choosing a professional service like Kwik Kar means you’re buying more than just a brake job; you're investing in experience, efficiency, and total peace of mind. A certified technician has seen it all and can spot underlying issues a DIYer might easily miss, like a failing caliper or a leaky brake line.

Professional shops are kitted out with diagnostic tools that go way beyond what’s in a home garage. This allows them to accurately check the entire braking system, ensuring worn pads aren't just a symptom of a much bigger, more expensive problem down the road.

One of the biggest perks of professional service is the warranty. When a shop does the work, they stand behind it. If a part fails too soon or something isn't right with the repair, you have a clear path to getting it fixed correctly, without the extra cost or headache.

And let's not forget about your time. A job that could eat up an entire Saturday for a novice is often wrapped up in just a couple of hours by an experienced mechanic. This gets you back on the road faster and, more importantly, with the confidence that the job was done to the highest safety standards.

Making Your Decision

To help you choose, it's helpful to see the two approaches side-by-side. Your final decision should really come down to your mechanical skill, what tools you have access to, and how much you value the guarantee that comes with professional work.

Brake Pad Replacement DIY vs Professional Service

| Factor | DIY Replacement | Professional Service (Kwik Kar) |

|---|---|---|

| Upfront Cost | Lower (parts only) | Higher (parts + labor) |

| Time Investment | High (several hours to a full day) | Low (typically 1-2 hours) |

| Required Expertise | Moderate to high mechanical skill needed | None required from the vehicle owner |

| Tools Required | Requires specialized tools | All necessary tools are on-site |

| Safety Assurance | Relies entirely on your own work | Backed by a professional warranty and expertise |

| Convenience | Low; requires space, time, and effort | High; drop-off and pickup service |

At the end of the day, while a DIY brake job is certainly possible for some, your braking system is the last place you want to cut corners. If you have any doubt at all about your ability to do the repair perfectly, trusting a professional is always the safest and most reliable move.

Simple Habits to Extend the Life of Your Brakes

Even though brake pads are meant to wear down eventually, your driving style and how you maintain your car can make a huge difference in how long they last. With a few small adjustments, you can seriously reduce brake pad wear, which means fewer trips to the shop and more money in your pocket. It all boils down to being a smarter, smoother driver.

The number one enemy of your brake pads is aggressive driving. Slamming on the brakes, tailgating, and racing toward red lights creates a massive amount of heat. That intense heat is what breaks down the friction material on your pads way faster than it should.

Instead, try to drive more defensively. Leave plenty of room between you and the car ahead. This simple habit gives you far more time to react, letting you slow down by just taking your foot off the gas. You'd be amazed how little you actually need to hit the brakes when you're anticipating traffic.

Let Your Engine Do Some of the Work

Your engine can be your best friend when it comes to controlling your speed, especially going down long hills. It’s a technique called engine braking, and it just means downshifting into a lower gear. When you do this, the engine's natural resistance helps slow the car down without you ever touching the brake pedal.

This keeps you from "riding the brakes," a habit that can easily overheat your pads and rotors. Overheating leads to faster wear and can cause a scary condition known as brake fade, where your brakes temporarily lose their stopping power. A quick downshift lets the engine take the strain, keeping your brakes cool and ready for when you really need them.

Lighten Your Load and Keep Your System Clean

It's just simple physics: the heavier your car is, the more work your brakes have to do to stop it. If you're hauling around a bunch of unnecessary junk in your trunk, you're forcing your brakes to work harder every single time you stop. Taking a few minutes to clear out heavy, non-essential items is an easy win for your brake pads.

Smart driving is key, but so is maintaining the entire brake system. Over time, your brake fluid absorbs moisture, which lowers its boiling point and can cause corrosion inside the system. Getting a regular brake fluid flush removes that old, contaminated fluid and helps your calipers and other parts move freely, preventing problems that lead to uneven or premature pad wear.

Following these simple habits can dramatically increase the lifespan of your brake pads:

- Look Ahead: See stops coming and ease off the gas to slow down gradually.

- Coast More: Let the car's momentum do the work instead of braking at the last second.

- Reduce Weight: Don't use your car as a storage unit for heavy items.

- Use Engine Braking: Downshift on long declines to give your brakes a break.

These little changes don't just save your brakes. They'll also help improve your gas mileage and make you a safer, more controlled driver overall.

Brake Pad Maintenance for Commercial Fleets

When you’re managing a commercial fleet, brake health isn't just another item on a maintenance checklist—it's at the very core of your budget and safety protocols. The challenges are completely different from a standard passenger car. Heavy payloads and the constant stop-and-go driving you see all over Dallas dramatically accelerate brake pad wear.

Putting it simply, a delivery truck that’s off the road for an unexpected repair isn't just an inconvenience. It's a direct hit to your bottom line. That vehicle downtime means missed deliveries, delayed service calls, and labor costs that just keep climbing. If brake pads fail unexpectedly, the damage can spread to rotors and calipers, turning a routine job into a major, expensive repair that sidelines a critical asset. Proactive management is the only way to shift brake care from a reactive cost into a real strategic advantage.

The Financial Case for Proactive Fleet Care

A scheduled maintenance program is your best defense against unplanned downtime. Instead of waiting for a driver to call in a grinding noise, a proactive approach catches wear long before it becomes a failure. This lets you schedule service during off-peak hours, keeping your vehicles on the road and earning when you need them most.

Another smart move is investing in heavy-duty brake components built for commercial use. These parts are engineered to handle much higher temperatures and greater stress. They offer a longer service life that ultimately reduces how often you need replacements. While the upfront cost might be slightly higher, it's easily paid back through lower long-term maintenance bills and more uptime.

The sheer scale of commercial brake maintenance is massive. Brake pads on these workhorses often last just 20,000-40,000 miles, a huge difference from the 50,000-mile average for a typical passenger car. With the global market for commercial vehicle brake parts valued at a staggering $35.79 billion in 2023, it’s clear how much your maintenance strategy impacts the bottom line.

Building a Reliable Maintenance Strategy

An effective fleet maintenance plan isn't something you can just improvise; it takes structure, consistency, and a service partner you can count on. It's how you protect your assets and stay compliant with safety regulations.

- Establish Regular Inspection Intervals: Don't just rely on the calendar. Base your inspection schedule on mileage and how each vehicle is used. A truck running city routes will need far more frequent checks than one doing long-haul highway miles.

- Track Wear Data: Keep detailed records of brake pad wear for every single vehicle in your fleet. This data is invaluable for predicting replacement needs and budgeting accurately.

- Partner with Experts: A trusted auto care provider can take the lead on your fleet's brake health, using quality parts and providing expert diagnostics that catch other potential issues before they become big problems.

The safety and longevity of your commercial fleet ride on diligent brake maintenance. And when it comes to managing fleet maintenance expenses, streamlined payment solutions can make the process much smoother, letting you focus on what really matters—keeping your vehicles on the road.

Your Trusted Partner for Brake Service in Dallas

We've covered a lot of ground in this guide. You now know how to spot the signs of brake pad wear and why getting ahead of brake problems is one of the most important things you can do for your vehicle's safety. From that first high-pitched squeal to doing a quick visual check, you're now in the driver's seat when it comes to your car's health. The next step is turning that knowledge into confident action.

When it comes to your brakes, there’s simply no room for guesswork. This system demands precision, real expertise, and top-quality parts to work flawlessly when you need it most. For drivers and fleet managers all over Dallas, putting this critical job in the hands of certified professionals is the best way to guarantee safety and peace of mind on the road.

Why Kwik Kar Is the Right Choice

At Kwik Kar, we don't just fix cars; we build relationships. We see ourselves as your partner in vehicle safety, committed to giving you honest advice and completely transparent service. Our technicians use state-of-the-art diagnostic tools to get a full picture of your entire braking system, ensuring we spot potential issues before they turn into dangerous—and expensive—problems.

We believe every single driver deserves to feel completely confident that their vehicle can stop safely, every time. That’s why we only use premium-quality brake pads and components, making sure every repair we do meets or exceeds what the manufacturer recommends for performance and durability.

We get it—your time is valuable. Our team works efficiently to get your vehicle serviced and back to you quickly, but never by cutting corners on quality. Whether you’re looking after the family car or managing a large commercial fleet, we deliver the reliable, expert care your vehicles deserve.

Don’t wait for a warning light to become an emergency. If you've noticed any of the symptoms we've talked about, or if it’s just been a while since your last brake check, it's time to take the next step. For a thorough and professional assessment, learn more about our expert brake services in Dallas and let our team make sure your vehicle is ready for the road ahead.

Ready to make sure your brakes are in top condition? Schedule a professional inspection with Kwik Kar Oil Change and Auto Care today and drive with total confidence. Book your appointment at https://www.kwikkarspringvalley.com.