For any fleet manager in Dallas, the constant pressure of rising fuel prices is an all-too-familiar headache. It's often the biggest and most unpredictable line item in your budget, but it doesn't have to be an uncontrollable one. Putting a solid plan in place to chip away at these expenses is one of the most powerful things you can do for your bottom line.

The good news? Significant savings are absolutely within your grasp. This isn't about finding a single magic bullet; it's about making smart, consistent improvements across your entire operation. A truly successful fuel-saving program is built on a few core strategies that all work together.

Your Blueprint For Cutting Fleet Fuel Expenses

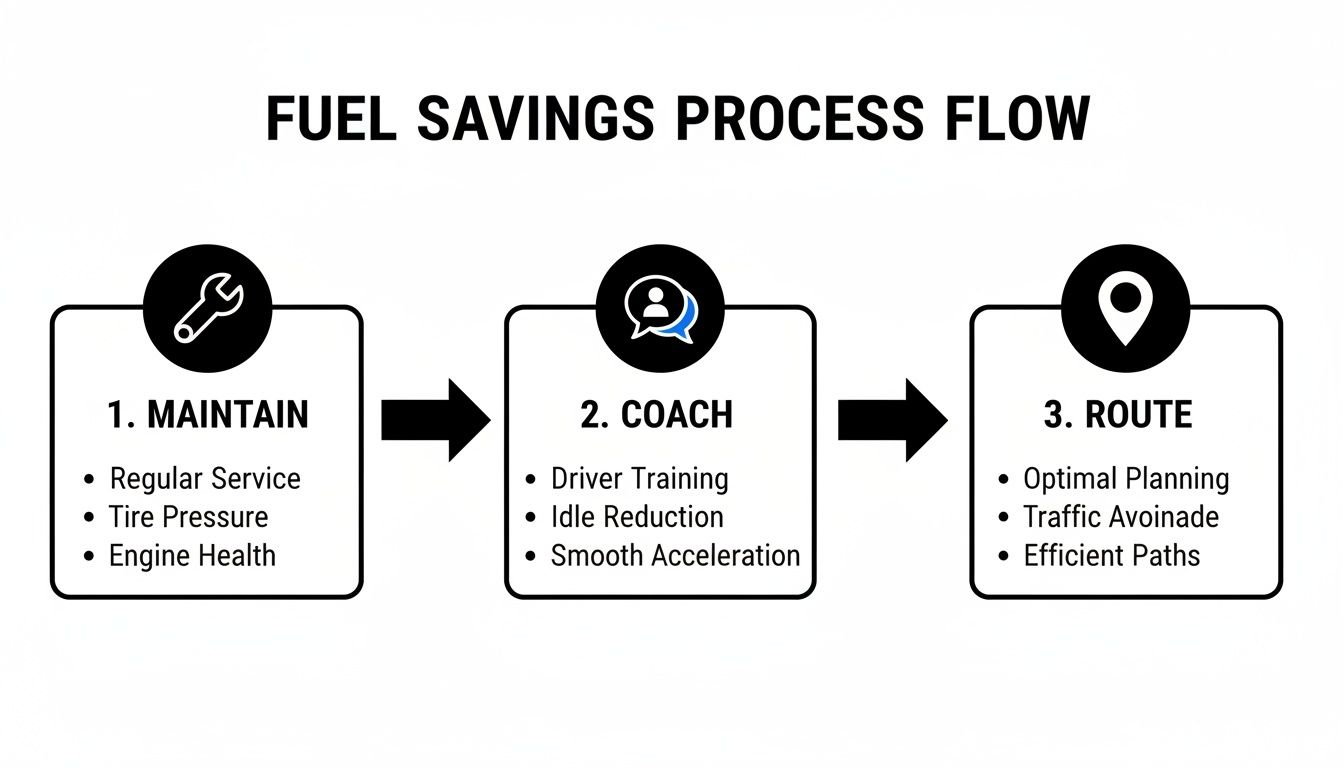

To get a real handle on fuel consumption, you need to attack it from multiple angles. It’s a combination of keeping your vehicles in top shape, making sure your drivers are efficient behind the wheel, and being smart about where and when they drive.

This simple flow shows just how interconnected these efforts are. Think of it as a continuous cycle of improvement that drives down costs month after month.

Why It Matters Now More Than Ever

Let's be blunt: fuel is the single largest expense for most fleets. It typically eats up 25-35% of total operating costs around the world, making it the number one target for savings. That slice of the pie has only gotten bigger as global fuel consumption continues to climb, with the U.S. leading the pack.

For fleet managers in Dallas overseeing sedans, SUVs, and light-duty trucks, this reality hits close to home. Even tiny gains in efficiency can translate into massive annual savings.

By focusing on these controllable factors, you transform fuel from a volatile, unpredictable expense into a manageable asset. The key is to start with a clear blueprint and commit to a culture of continuous improvement.

We've found that the most successful programs are built on four key pillars. Focusing your energy here will give you the best return on your efforts.

The Four Pillars of Fleet Fuel Cost Reduction

Here’s a quick breakdown of the core strategies every fleet manager should have in their playbook and the kind of impact they can have.

| Strategy Pillar | Key Actions | Estimated Fuel Savings |

|---|---|---|

| Proactive Vehicle Maintenance | Regular synthetic oil changes, proper tire inflation, engine tune-ups, and scheduled inspections. | 10-15% |

| Impactful Driver Coaching | Training to reduce speeding, hard acceleration/braking, and excessive idling. | 5-30% |

| Strategic Route Optimization | Using telematics and software to find the most efficient routes and minimize mileage. | 10-20% |

| Intelligent Fuel Purchasing | Using fleet fuel cards to monitor spending, prevent theft, and analyze purchasing data. | 5-15% |

Each of these pillars contributes to the bigger picture, and when combined, they create compounding savings that really add up.

For a longer-term strategy, it's also worth exploring how alternatives like Natural Gas in Transportation can offer cleaner and more cost-effective operations.

Here at Kwik Kar, we partner directly with Dallas fleet managers to lock down the maintenance pillar of this strategy. Our goal is to make sure your vehicles are always running at peak efficiency, maximizing your uptime and keeping that fuel spend as low as possible.

Find out more about our specialized fleet services and how we can help you build a more profitable operation.

Turn Your Maintenance Bay into a Fuel Savings Center

For far too long, fleet managers have seen vehicle maintenance as just another cost center. It's a necessary evil, a line item on the budget that only seems to go up.

But what if you started looking at every oil change, tire rotation, and engine check-up differently? What if each service wasn't an expense, but a direct deposit into your fuel savings account? Making that mental shift is the first real step toward slashing your fleet's biggest variable cost.

Proactive, high-quality maintenance is hands-down one of the most powerful tools you have to fight back against high fuel prices. A vehicle that's not running right doesn't just risk a breakdown; it's actively burning through your profits with every inefficient mile.

The Unbreakable Link Between Upkeep and MPG

Every single component in your vehicles is designed to work together for peak performance. When one part is neglected, it starts a domino effect that almost always ends with higher fuel consumption. Think of it like a pro athlete—you can't win the game if you're running on a sore ankle.

The connection is surprisingly direct. Experts are forecasting that predictive and preventive maintenance programs will deliver up to a 30% reduction in fleet maintenance costs by 2030. That's a huge number, and a big chunk of it comes from cutting the fuel waste caused by inefficient vehicles.

When you consider that fuel can eat up 35% of your total operating costs, with per-mile expenses recently hitting $0.202, the financial incentive is crystal clear. In fact, getting your maintenance and fuel data to talk to each other can even boost vehicle uptime by 15%, turning garage time back into productive road time. You can dig deeper into these numbers with some of the latest fleet management trends from Element Fleet.

The "Big Four" Maintenance Tasks for Fuel Efficiency

You don't need a complete overhaul to see results. Focusing on just a few key areas will give you the biggest bang for your maintenance buck. These are simple, repeatable tasks that have a massive impact on your fleet's fuel bill.

- Go with Synthetic Oil: Using a high-quality synthetic oil is a no-brainer. It dramatically reduces engine friction, meaning the engine doesn't have to work as hard. Less work equals less fuel burned on every single trip.

- Keep Tire Pressure on Point: This is the easiest, cheapest win you can get. Under-inflated tires create more rolling resistance, forcing the engine to burn extra fuel just to maintain speed. A quick weekly check can boost mileage by up to 3%.

- Change Those Air Filters: Your engine needs to breathe. A dirty, clogged air filter is like forcing it to run a marathon while breathing through a straw. A clean filter lets air flow freely, and it's a fast, cheap fix with an immediate payoff.

- Check Your Wheel Alignment: When wheels are misaligned, they drag instead of roll. This not only chews up your tires but also puts a constant strain on the engine, wasting fuel every mile. A proper proper 4-wheel alignment is critical for efficiency.

A well-maintained vehicle is an efficient vehicle. Period. By treating maintenance as a proactive strategy, you’re not just preventing breakdowns—you're actively optimizing every single gallon of fuel you buy.

A Sample Maintenance Schedule Built for Dallas Fleets

Let's be honest, Dallas driving is brutal on vehicles. The intense heat and relentless stop-and-go traffic mean a generic, by-the-book maintenance schedule just won't cut it. Your fleet needs a "severe duty" approach to stay efficient.

Here’s a practical schedule you can adapt for your light-duty trucks, cars, or SUVs running around the DFW metroplex.

| Maintenance Task | Frequency | Why It Saves Fuel |

|---|---|---|

| Tire Pressure Check | Weekly | Prevents increased rolling resistance from under-inflation. |

| Synthetic Oil & Filter Change | Every 5,000 miles | Ensures minimal engine friction and optimal performance. |

| Air Filter Inspection | At every oil change | Guarantees the engine has unrestricted airflow for efficient combustion. |

| Tire Rotation & Balance | Every 5,000–7,500 miles | Promotes even tire wear, reducing road resistance. |

| Wheel Alignment Check | Every 12,000 miles or annually | Eliminates tire drag that forces the engine to overwork. |

| Engine Tune-Up | Per manufacturer specs | Replaces worn spark plugs and components for a clean, efficient burn. |

Partnering with a local shop like Kwik Kar puts this entire schedule on autopilot. We know what Dallas driving does to a vehicle, and we can build a fleet maintenance program that turns your upkeep budget into a powerful fuel-saving tool. The goal is simple: keep your vehicles on the road serving customers, not sitting at the pump.

Coaching Drivers for Maximum Fuel Efficiency

Once you've got your maintenance dialed in, the single biggest lever you can pull to slash your fuel budget is sitting right in the driver's seat. Your team has more control over that fuel gauge than any piece of technology you can install. The key is to build a fuel-conscious culture—not by hammering down harsh rules, but through coaching, collaboration, and turning your drivers into genuine partners in cutting costs.

Even a perfectly tuned truck will guzzle fuel if it's driven aggressively. The goal is to pinpoint the exact behaviors that burn the most diesel and use hard data to have constructive conversations, not punitive ones.

Targeting the Top Three Fuel-Wasting Habits

While lots of things can affect fuel burn, I've found that three specific habits are almost always the biggest culprits. Since driver behavior can swing fuel consumption by as much as 30%, focusing your coaching here will give you the fastest, most significant returns.

- Aggressive Driving: This is your classic jackrabbit starts, hard braking, and tailgating. Every time a driver floors it or slams on the brakes, they're basically just turning fuel into wasted heat and momentum. Smooth and steady is the name of the game.

- Excessive Idling: An idling engine gets exactly zero miles per gallon. It sounds obvious, but the U.S. Department of Energy says over six billion gallons of fuel are torched every year from idling alone. It’s a habit that costs fleets a fortune, especially during drop-offs, pickups, or breaks.

- Speeding: Fuel efficiency really starts to nosedive at speeds over 55-60 MPH. Think about it: for every 5 MPH over 60, a truck can lose an average of 0.7 MPG. On the highways around Dallas, that tiny difference adds up to staggering costs over thousands of miles.

Using Telematics Data for Constructive Coaching

Modern telematics systems are your secret weapon here. They provide objective, indisputable data that changes the entire conversation. You're no longer saying, "You seem to drive too fast." Instead, you can have a productive, fact-based review: "Let's look at last week's report—it shows three speeding events over 75 MPH on the Tollway."

The trick is to use this data positively. Frame these one-on-one meetings as chances for professional growth.

Scenario Example: Instead of leading with a negative, try a more collaborative approach. "John, I saw your truck's idling time was about 25 minutes higher than the fleet average yesterday. Was there a big delay at the Richardson site, or is there something we can do to help get that down?" This opens up a dialogue instead of immediately putting the driver on the defensive.

This approach shows you respect their expertise and makes them part of the solution.

Building a Fuel Efficiency Policy That Works

A formal policy is crucial because it sets clear, consistent expectations for the whole team. It gets rid of any gray areas and gives you a solid foundation for your coaching. But a good policy isn't just a list of "don'ts"—it should also include incentives that reward your top performers.

Your policy needs to clearly define what you expect around those "big three" fuel-wasting habits and spell out how you'll measure performance.

Sample Fuel Efficiency Policy Components

| Policy Section | Key Guidelines |

|---|---|

| Speed Management | All vehicles must stick to posted speed limits. We're setting our maximum highway speed at 68 MPH, even if the limit is higher, to optimize fuel burn. |

| Idle Reduction | Engines have to be turned off if the vehicle is going to be stationary for more than 3 minutes, unless it's needed for PTO operation. |

| Driving Conduct | We expect smooth acceleration and braking. Maintain a safe following distance so you can anticipate traffic and avoid sudden stops. |

| Performance Review | We'll review driver scorecards from telematics data every month. Scores will be based on speeding, idling, and harsh driving events. |

| Incentive Program | Drivers in the top 10% for fuel efficiency each quarter will get a $150 bonus. The top driver for the year receives an extra $500 bonus. |

This blend of clear rules and positive reinforcement is a powerful motivator. It turns compliance into a bit of friendly competition, and when that happens, everybody wins. When you empower your drivers with knowledge and reward their hard work, you build a lasting culture of efficiency that continuously works to lower your fleet's fuel costs and boost your bottom line.

Using Technology for Smarter Routes and Operations

Trying to run your fleet on gut instinct or old paper maps is like navigating Dallas traffic with a blindfold on. It’s not just inefficient; it’s incredibly expensive. In modern fleet management, your most powerful weapon against high fuel costs is data. Technology like telematics and route optimization software isn't some fancy add-on anymore—it's absolutely fundamental to running a profitable operation.

These systems do so much more than just basic GPS tracking. They give you a real-time, bird's-eye view of your entire fleet, letting you make instant, data-driven decisions that cut down on mileage, sidestep costly traffic jams, and put a stop to wasteful engine idling. The return on investment here is often surprisingly fast, turning what you pay for a software subscription into real savings at the pump each month.

Go From Guesswork to Precision Route Planning

At its heart, route optimization is all about finding the absolute shortest and most efficient path between all your stops. Software can figure this out in seconds—a task that would take a human planner hours—while also factoring in traffic patterns, specific delivery windows, and how much each vehicle can carry. This hits on the most basic principle of saving fuel: drive fewer miles.

By getting rid of unnecessary backtracking and drivers going off-route, many fleets see an immediate 10-20% drop in what they spend on fuel. Just picture a typical day for one of your Dallas delivery drivers. Without a good system, they might end up crisscrossing the city, hitting stops in a random order that just burns through time and diesel.

With the right tech, that exact same schedule gets organized into a smart, logical sequence that cuts down travel time and gets more done.

Navigating Real-World Scenarios in Real Time

Where this technology really proves its worth is when the unexpected happens. Let's paint a picture of a classic Dallas traffic nightmare.

Real-World Example: One of your trucks is heading north on I-35E near downtown to make a time-sensitive delivery. Out of nowhere, a major wreck shuts down every single northbound lane. Without telematics, your driver is now stuck, just sitting there burning fuel in a standstill that could last for hours. But with a modern system, you see that backup forming on your dashboard in real time. You can instantly reroute your driver over to the Dallas North Tollway, letting them bypass the whole mess.

In that one situation, you just saved:

- Gallons of wasted fuel from sitting in traffic.

- Hours of lost productivity for that driver.

- The risk of a late delivery fee and an unhappy customer.

This ability to adapt on the fly turns unpredictable chaos into a manageable problem, directly protecting your bottom line.

Tackling the Silent Killer of Your Fuel Budget

Excessive idling is one of the sneakiest and most expensive habits a fleet can have. An idling engine is doing literally nothing but burning through your fuel budget, and the costs are genuinely shocking. The U.S. Department of Energy figures that over six billion gallons of fuel are wasted every year just from idling vehicles.

Telematics finally gives you the hard data you need to get this problem under control. Modern systems can generate detailed reports on idling, pinpointing exactly which drivers, vehicles, or even specific locations are the worst offenders. You might find out a driver consistently leaves the truck running for 30 minutes during their lunch break, or that a certain delivery site always has long wait times.

Armed with that knowledge, you can create and enforce a clear anti-idling policy. You can coach the drivers who need it most or have a conversation with the managers at problem locations to speed things up. It’s a targeted approach that works far better than just sending out a generic memo because it’s backed by objective, undeniable data—a key strategy for how to reduce fleet fuel costs.

Optimizing Your Fleet Composition and Fuel Purchasing

While driver coaching and route planning offer some quick wins, your biggest long-term savings are tied up in two core areas: the vehicles you buy and how you pay for fuel. Getting these strategic decisions right creates a foundation for efficiency that will pay you back for years.

The first big mind-shift is to stop focusing on sticker price. Experienced fleet managers live and breathe by Total Cost of Ownership (TCO). This calculation looks at the entire picture—not just the initial purchase, but also fuel, maintenance, insurance, and what you’ll get back at resale. A cheaper truck up front can easily become your most expensive asset if it's always at the pump or in the shop.

Thinking Beyond the Sticker Price with TCO

When you start analyzing vehicles through a TCO lens, the math can really surprise you. For a fleet in Dallas dealing with constant stop-and-go traffic, a hybrid or even an EV might have a higher purchase price, but its TCO is often dramatically lower thanks to huge savings on fuel and maintenance.

This isn't just a theory; it's happening right now. Projections show that switching to hybrids and EVs could slash fleet fuel demand by at least 15% before 2030. With U.S. EV sales expected to hit 1.3 million in 2024 and global sales jumping 26%, the momentum is clear, especially for light trucks and SUVs.

To see how this plays out, let's look at a simplified TCO snapshot comparing two light-duty trucks operating in the Dallas area over a five-year lifespan.

TCO Snapshot: Gasoline vs. Hybrid Light Truck

| Cost Factor | Gasoline Light Truck | Hybrid Light Truck |

|---|---|---|

| Initial Purchase Price | $45,000 | $52,000 |

| Estimated 5-Year Fuel Cost | $28,000 | $16,500 |

| Estimated 5-Year Maintenance | $8,500 | $6,000 |

| Total Cost of Ownership | $81,500 | $74,500 |

Even with a higher initial cost, the hybrid model ends up saving $7,000 over its service life. Now, multiply that across a fleet of just ten trucks, and you’re looking at $70,000 added directly to your bottom line. As you explore this shift, it's also crucial to understand the costs of electric charging for businesses, as managing that expense is a key part of the TCO puzzle.

Making Fuel Purchasing a Strategic Advantage

How you buy fuel is just as critical as how much your vehicles burn. Letting drivers pay with cash or personal cards is a recipe for chaos. It’s inefficient, opens the door to potential fraud, and leaves you with zero useful data. The solution is a solid fuel purchasing strategy built on control and information.

One of the most effective moves you can make is implementing a fleet fuel card program. These cards are much more than just a way to pay; they are powerful data-gathering tools.

By centralizing your fuel spending through a dedicated card program, you transform random, untraceable expenses into a clear, actionable dataset. You gain complete visibility into every gallon purchased, which is essential for any serious cost-reduction effort.

A good fuel card program gives you the power to:

- Set Purchase Controls: You can limit spending to fuel only, block purchases outside of work hours, or even cap the number of gallons per fill-up to prevent misuse.

- Capture Detailed Data: Every swipe records the vehicle, driver, location, time, fuel grade, and cost. This is the raw data you need to track MPG and spot problems.

- Simplify Reporting: Automated reports can save you countless hours of administrative work and make things like IFTA tax reporting much more manageable.

This level of insight and control is something you'll never get from a standard credit card. And while you're optimizing your purchasing, don't forget the basics—check out our guide on essential tire maintenance tips to see how simple upkeep complements a smart buying strategy. When you combine the right vehicles with a smart fuel plan, you create a powerful one-two punch that tackles fleet fuel costs at their core.

Building Your Continuous Improvement Plan

Here’s the thing about reducing fleet fuel costs: it's not a one-and-done project. Think of it as a continuous loop—you monitor, you adjust, and you keep refining your strategy. All the individual tactics we've talked about, from oil changes to driver coaching, need to come together into a sustainable, long-term program.

The real goal is to build a culture where efficiency is always top of mind. When you do that, you start turning small, consistent wins into significant savings by the end of the year.

First, Know Your Starting Line: Establishing a Fuel Efficiency Baseline

You can't manage what you don't measure. It’s an old saying, but it’s absolutely true in fleet management. Before you can make any real progress, you have to establish a clear baseline. This gives you a concrete number to improve upon and helps you set realistic goals for the months ahead.

While miles per gallon (MPG) is a common metric, I've found a more powerful KPI for business operations is cost-per-mile (CPM). Why? Because it accounts for both fuel price swings and vehicle efficiency, giving you a much truer picture of your operational costs.

Calculating it is straightforward. Just divide your total fuel cost for a given period (say, a month) by the total miles driven in that same period.

For example, let's say your fleet spent $15,000 on fuel last month and drove a combined 75,000 miles. Your baseline CPM is $0.20. A solid, achievable goal might be to knock that down to $0.19 next quarter. That's a 5% reduction, which might not sound like much, but it translates directly to $9,000 in annual savings.

The Monthly Fuel Cost Review

Once you have your baseline, the next move is setting up a simple, repeatable review process. A monthly "Fuel Cost Review" meeting is perfect for keeping the momentum going and holding everyone accountable.

This doesn't need to be a long, drawn-out affair. Keep the discussion focused on a handful of critical data points:

- Overall Fleet MPG and CPM: Are the top-level numbers moving in the right direction?

- Idling Time Per Vehicle: Who are the biggest offenders? Has the coaching you gave last month's problem drivers made a difference?

- Driver Performance Scores: Take a moment to highlight your top performers. It’s just as important to recognize good work as it is to identify who might need a bit more coaching on things like speeding or harsh braking.

This regular check-in transforms your fuel-saving efforts from a bunch of scattered tasks into a cohesive, data-driven program. It creates a rhythm of accountability and ensures that the mission of how to reduce fleet fuel costs stays front and center, continuously protecting your bottom line.

Your Top Questions About Fleet Fuel Costs, Answered

Even with the best game plan, some questions always pop up when you start putting it into action. As a fleet manager, you're constantly balancing cost, efficiency, and performance. Here are some straight-talking answers to the most common hurdles I see managers face when they decide to get serious about their fuel budget.

What's the Fastest Way to See Fuel Savings?

Honestly, the quickest win is always focusing on your drivers. While optimizing maintenance and routes are absolutely critical for long-term savings, changing habits behind the wheel gives you the biggest bang for your buck, right away.

You can see a difference almost overnight just by cracking down on excessive idling. A simple policy change can make an immediate dent. From there, coaching your team to ease up on the gas pedal and avoid slamming on the brakes can cut fuel use by 5-10% nearly instantly. The best part? This doesn't cost a dime in new equipment—just clear communication and making sure everyone sticks to the plan.

How Often Should We Really Be Servicing Our Fleet Vehicles?

For any commercial fleet running hard in the Dallas area, my advice is to stick to the manufacturer's "severe duty" maintenance schedule. The standard intervals just don't cut it with our stop-and-go traffic and brutal summer heat.

That means getting a little more aggressive with your preventive care:

- Synthetic Oil Changes: Think about getting these done every 5,000 miles. Good, clean oil keeps engine friction low, which is a direct win for fuel economy.

- Tire Pressure Checks: This needs to be a weekly ritual. It's simple, but keeping tires properly inflated can boost your mileage by up to 3%. That adds up fast.

- Air Filter Inspections: Have your technician peek at the air filter during every oil change. A clogged filter suffocates the engine, forcing it to burn more fuel.

A tight, consistent program like this stops fuel waste before it even starts.

Is Telematics Software Really Worth It for a Small Fleet?

Absolutely. I know the upfront cost can look intimidating, but the return on investment for telematics is surprisingly quick, even if you only have five or ten vehicles. Most systems pay for themselves within just a few months.

The real value of telematics is that it gives you hard data on things you can't otherwise see. And you can't fix what you can't measure.

This tech shines a spotlight on the "big three" fuel wasters: idling, speeding, and bad routing. Armed with that data, you can make targeted changes and provide specific, helpful coaching to your drivers. Many managers I've worked with also find it improves safety and even helps them get better insurance rates, which makes the investment a no-brainer.

Ready to turn your maintenance program into a powerful tool for cutting fuel costs? The experts at Kwik Kar Oil Change and Auto Care specialize in creating custom fleet service plans that keep your Dallas vehicles running efficiently and reliably. Learn more and schedule your fleet consultation today!