A fleet preventive maintenance program is really just a game plan for taking care of your vehicles before they break down. It involves a routine schedule of inspections, servicing, and replacing parts that are known to wear out. The whole point is to keep your fleet in top shape and stop unexpected failures in their tracks. This flips the script from constantly putting out fires to having a smart system that keeps your vehicles on the road, earning money.

What a Fleet Preventive Maintenance Program Actually Is

Think about it like a professional athlete’s training routine. An athlete doesn't just sit around waiting for an injury to happen. They follow a strict plan—stretching, proper nutrition, consistent training—to stay at peak performance and avoid getting hurt in the first place.

That’s exactly what a good maintenance program does for your fleet. It’s all about prevention, not reaction. It’s the difference between swapping out worn brake pads for a predictable cost versus a full-blown roadside breakdown that racks up bills for towing, rotor damage, and a ton of lost time.

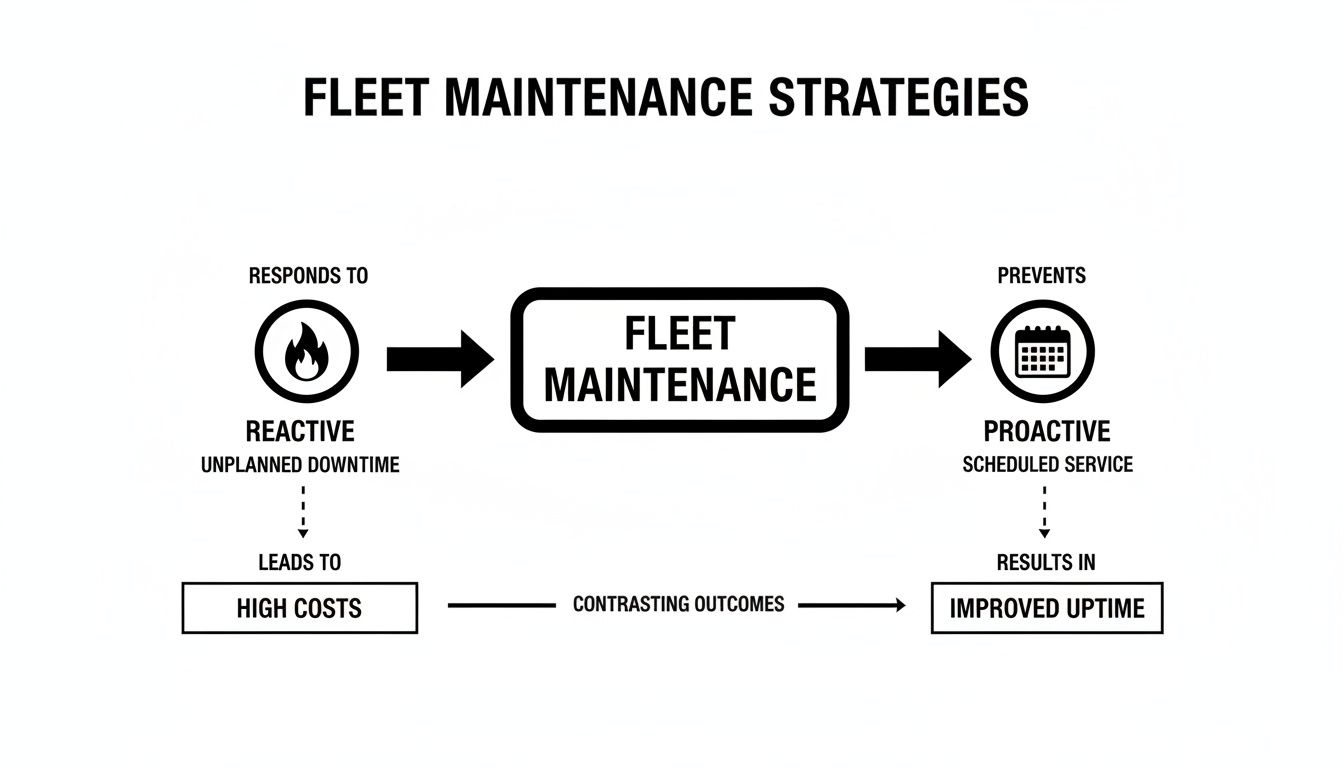

Shifting from Reactive to Proactive

The old-school way of handling vehicle care is the "break-fix" method. You run a vehicle until something fails, which immediately pulls it out of service without warning. For any business that depends on its vehicles, this reactive approach is a nightmare for efficiency and your budget. Every minute a service truck or delivery van is sidelined, it’s a direct hit to your bottom line.

A fleet preventive maintenance program completely changes that dynamic. Instead of just reacting to emergencies, you’re the one in control of the schedule. This forward-thinking strategy is built on a few core principles:

- Scheduled Servicing: Maintenance happens on your terms, planned around your business operations, not dictated by a sudden breakdown.

- Systematic Inspections: Regular check-ups are designed to catch the small stuff—like a frayed belt or a minor leak—before they snowball into major, expensive repairs.

- Data-Driven Decisions: The program should use real data like mileage, engine hours, and inspection reports to figure out the perfect time for service.

By moving from a reactive to a proactive model, fleet managers can slash expensive downtime and keep vehicles out on the road where they belong. It’s a crucial investment in operational efficiency, safety, and long-term profitability.

At the end of the day, this system isn't just about dodging repairs; it's a core business strategy. It helps you squeeze more life out of your most valuable assets, keeps your drivers safe, and builds a reliable, professional fleet that your customers can depend on. The goal is to turn maintenance into a predictable, manageable expense instead of a constant stream of costly surprises.

The Building Blocks of a Strong Maintenance Program

A solid fleet preventive maintenance program isn’t just one action—it's a complete system where every part works together. Think of it like a high-performance engine; for the whole machine to run smoothly and reliably, each component has to be perfectly calibrated. If you let one piece slide, the entire system suffers.

This system is built on five fundamental pillars: smart scheduling, thorough inspections, standardized checklists, strategic parts management, and meticulous recordkeeping. When you get these elements right, maintenance stops being a reactive chore and becomes a strategic advantage that prevents failures before they can ever sideline your operations.

This visual perfectly captures the shift from the expensive, fire-fighting approach of reactive repairs to a value-driven, proactive one.

The goal is to move away from the chaos of emergency repairs and into the calm, controlled world of planned maintenance.

Smart Scheduling Beyond the Basics

The schedule is the heart of any preventive maintenance program. But an effective, modern schedule is much more than just putting a reminder on the calendar every six months. It's a dynamic plan that adapts to the real-world demands placed on each and every vehicle.

Manufacturer recommendations are a great starting point, but a one-size-fits-all approach just doesn't cut it for a diverse fleet. A delivery van that logs hundreds of miles a day in stop-and-go city traffic has completely different needs than an executive sedan used for occasional client visits.

Truly effective scheduling pulls in multiple data points to trigger maintenance at the perfect moment:

- Mileage: The classic metric for service intervals, perfect for vehicles with consistent, predictable usage.

- Engine Hours: This is critical for vehicles that spend a lot of time idling, like utility trucks or local delivery vans. An engine can rack up serious wear and tear even when the odometer isn't moving.

- Time-Based Intervals: Essential for catching issues like fluid degradation or rubber component aging that happen over time, regardless of how much the vehicle is used.

- Telematics Data: Modern systems can flag fault codes and monitor vehicle performance in real time, giving you a heads-up on potential issues long before they become catastrophic failures.

The Power of Consistent Inspections

If scheduling is the heart of the program, inspections are its eyes and ears. They are your first line of defense against unexpected downtime, catching small problems before they balloon into major, expensive repairs. Spotting a loose hose or a worn belt during a routine check can save you thousands in emergency repair bills and lost revenue down the road.

These inspections happen at different levels. The most frequent is the Driver Vehicle Inspection Report (DVIR). Your drivers are the first to notice if something feels off—a weird noise, a slight vibration, or a new warning light. Giving them a simple, daily checklist empowers them and turns them into a crucial part of your maintenance intelligence network.

Beyond the DVIR are the more detailed technical inspections done by skilled mechanics. These deeper dives assess the health of critical systems like brakes, suspension, and the powertrain, ensuring every component is safe and in good working order.

A robust inspection process doesn't just prevent breakdowns; it builds a culture of safety and accountability across your entire team.

Standardized Checklists and Smart Parts Management

To make sure inspections are always thorough and consistent, you need standardized checklists. A generic list won't do; checklists should be customized for different vehicle types and their specific jobs. To see what a good one looks like, check out our detailed guide on the essential elements of a comprehensive vehicle inspection checklist.

Just as important is how you manage your parts inventory. A great program strikes a balance between having critical parts on hand to keep downtime to a minimum and not tying up too much cash in excess stock. The goal is simple: have the right part, at the right time, for the right price.

Meticulous Recordkeeping is Your Proof

Finally, what holds this whole system together is meticulous recordkeeping. Every single inspection, service, and repair needs to be documented. This data is pure gold for several reasons:

- Compliance: It creates a clear, auditable trail that proves you're following regulations from agencies like the Department of Transportation (DOT).

- Trend Analysis: It lets you spot patterns. Maybe one specific vehicle model is having frequent brake issues? This data allows you to adjust your maintenance strategy accordingly.

- Proving ROI: It gives you the hard data you need to show the program's value by tracking metrics like reduced downtime and a lower cost-per-mile.

Without solid records, you’re flying blind. With them, you have the insights needed to constantly refine and improve your entire fleet preventive maintenance program.

Understanding the Financial Impact of Your Program

Any good fleet preventive maintenance program has to prove its worth in dollars and cents. This isn't just about operational theory; it's about seeing a real, measurable impact on your bottom line by lowering the Total Cost of Ownership (TCO) for every vehicle.

The idea is simple: you're choosing to spend a little now to avoid spending a lot later.

Think about the difference between a scheduled $150 brake pad replacement and a sudden, catastrophic failure on the road. That surprise breakdown isn't just about new pads. It quickly balloons into a $1,000+ emergency bill that includes destroyed rotors, damaged calipers, towing fees, and the massive headache of a vehicle being pulled from service without warning.

This is the fundamental shift from reactive firefighting to proactive management. It’s where you start to see a real return on your investment.

Slashing Costs Beyond Emergency Repairs

The financial wins from a solid program go way beyond just dodging those dramatic roadside breakdowns. Maintenance is a huge chunk of any fleet’s budget. Here in North America, it's a $75 billion annual market, and smart fleet managers are using preventive strategies to get a handle on those climbing costs.

For many fleets, maintenance eats up 30-50% of the TCO, which makes proactive care one of the most powerful financial levers you can pull.

Here are a few other ways a consistent program trims your operational spending:

- Better Fuel Economy: An engine that's properly maintained—with clean oil, correct fluid levels, and properly inflated tires—just runs better. It’s more efficient. That means you're burning less fuel per mile, a saving that adds up incredibly fast across a whole fleet.

- Longer Vehicle Lifespan: Nothing keeps your vehicles on the road longer than regular maintenance. When you catch and fix the small stuff early, you stop the little problems that add up over time and eventually send an asset to the scrapyard. This means you can put off major capital expenses for new vehicles.

- Higher Resale Value: A truck or van with a complete, detailed service history is a golden ticket on the used market. Buyers will pay a premium for an asset they know has been taken care of, giving you one last financial win when it's time to upgrade.

And as you calculate the financial impact, don't forget vehicle-specific costs, like the unique service needs and electric car maintenance costs for fleets adding EVs to the mix.

Let's look at a clear example of how these costs stack up.

Preventive vs. Reactive Maintenance Cost Comparison

| Maintenance Item | Preventive Action and Cost | Reactive Repair and Cost | Potential Savings |

|---|---|---|---|

| Brake System | Routine Inspection & Pad Replacement: $250 | Caliper/Rotor Failure & Towing: $1,200+ | $950+ |

| Engine Oil | Scheduled Oil & Filter Change: $75 | Engine Damage from Oil Sludge: $4,000+ | $3,925+ |

| Tires | Regular Rotation & Inflation Checks: $50 | Premature Wear & Blowout: $800+ | $750+ |

| Transmission | Fluid Flush at Recommended Interval: $200 | Complete Transmission Rebuild: $3,500+ | $3,300+ |

As the numbers show, the choice is pretty stark. A small, planned expense consistently saves you from a budget-busting emergency down the line.

The True Cost of Downtime

Often, the biggest financial hit from a reactive "fix-it-when-it-breaks" approach isn't even the repair bill. It’s the cost of downtime.

Every single hour a vehicle is unexpectedly sitting in a shop, it's losing money. A delivery van that's out of commission isn't making deliveries. A service truck can't get to job sites. An executive car isn't getting people to important meetings.

A fleet preventive maintenance program is designed to trade unscheduled, high-cost downtime for planned, low-impact service appointments. This ensures your revenue-generating assets are on the road, where they belong.

This proactive approach lets you schedule service during off-peak hours or when you have a backup vehicle ready to go. It turns maintenance from a crisis into just another manageable part of doing business. Improving fuel consumption is another key benefit; you can learn more by checking out our guide on how to reduce fleet fuel costs.

Ultimately, having that control over your schedule and expenses gives you the stability and predictability you need to run a profitable, reliable operation.

How to Implement Your Fleet Maintenance Program

Making the switch from a reactive, "break-fix" mindset to a proactive fleet maintenance program can feel like a massive undertaking. But it's not. Think of it as creating a custom workout plan for your fleet. You start by figuring out where your vehicles are today, set some realistic goals, and then build a consistent routine to get them—and keep them—in top shape.

This isn't about flipping a switch and changing everything overnight. It's about taking a measured, step-by-step approach to get a handle on your fleet, cut down on unexpected costs, and keep every vehicle on the road where it belongs. Let's walk through the roadmap for turning your maintenance strategy into a real operational advantage.

Step 1: Start with a Thorough Fleet Assessment

Before you can chart a course forward, you have to know exactly where you're starting from. The first real step is creating a complete, accurate inventory of every single asset in your fleet. This baseline is the bedrock your entire maintenance strategy will be built on.

For each vehicle, you'll want to gather some key details:

- Core Vehicle Details: Year, make, model, and VIN.

- Operational Information: Current mileage or engine hours, which driver or department uses it, and how it's typically used (e.g., constant city driving vs. long highway miles).

- Service History: Dig up all the maintenance records you can find. This will tell you about past repairs, any nagging issues, and existing warranty information.

This initial dive gives you a clear snapshot of your fleet's health, age, and the demands placed on it. It immediately helps you spot the high-risk vehicles, see what's due for a major service, and uncover where your maintenance blind spots might be.

Step 2: Define Clear Goals and KPIs

Once you have a full picture of your fleet, it's time to decide what "success" actually looks like. Vague goals like "improve uptime" just won't cut it. You need specific, measurable targets—Key Performance Indicators (KPIs)—to guide your program and prove it's working.

Your goals should tie directly to business results. For instance, instead of just aiming to "reduce costs," set a concrete target to lower your cost-per-mile by 15% within the first year.

Setting clear, data-driven goals transforms your maintenance program from a simple to-do list into a strategic business initiative. It gives your team a finish line to cross and provides a concrete way to demonstrate the program's value to the higher-ups.

Consider setting KPIs for a few key areas:

- Vehicle Uptime: Shoot for a target like 95% vehicle availability during work hours.

- Maintenance Costs: Set a goal to slash unscheduled repair expenses by 25%.

- PM Compliance: Aim for a 90% or higher completion rate on all scheduled preventive maintenance.

These numbers give you a benchmark. You can look back in a few months and see exactly what's working and where you need to make some tweaks.

Step 3: Develop Custom Maintenance Schedules

One of the biggest pitfalls in fleet maintenance is using a one-size-fits-all schedule. A delivery van racking up miles all day needs a much more aggressive service plan than an executive sedan that's barely used. Using the data from your fleet assessment, you can build out schedules tailored to different vehicle groups.

Start with the manufacturer's (OEM) recommendations as your foundation. That’s the expert advice on how to keep their vehicles running right. But then, you have to adjust for the real world.

A truck operating in the brutal Texas heat or stuck in Dallas stop-and-go traffic is going to need more frequent fluid changes and brake checks than the owner’s manual suggests. Your schedules should be living documents, using a mix of mileage, engine hours, and calendar time to trigger service reminders.

Step 4: Train Your Team and Leverage Technology

Your drivers are your first line of defense. They're in the vehicles every day, and they're the first ones to notice when something sounds, feels, or smells off. A mandatory Driver Vehicle Inspection Report (DVIR) process is absolutely essential. Train your drivers what to look for during simple pre-trip and post-trip walkarounds.

Giving them a simple checklist can help catch small issues—a soft tire, a flickering light—before they turn into a major breakdown on the side of the road. It also builds a culture where everyone feels responsible for the fleet's health.

On top of that, use technology to make this all manageable. Fleet maintenance software can automate service reminders, track work orders, and keep a detailed service history for every asset. It gets you out of the messy world of spreadsheets and ensures no critical maintenance task gets missed.

Step 5: Review and Continuously Improve

A truly effective fleet preventive maintenance program is never really "done." It’s a living system that needs to be watched and fine-tuned. Schedule regular reviews—maybe quarterly or every six months—to sit down and look at your KPI data.

During these meetings, ask the tough questions:

- Are we hitting our uptime and cost-per-mile goals?

- Are we seeing a pattern of the same failures on certain types of vehicles?

- Is our PM schedule actually working, or do the intervals need to be adjusted?

This continuous feedback loop is what allows you to make smart, data-driven decisions to optimize the whole program. By analyzing trends and spotting areas for improvement, you ensure your maintenance strategy keeps evolving right alongside your fleet, delivering maximum value for the long haul.

Measuring Success with Key Performance Indicators

A fleet preventive maintenance program is only as good as the results it delivers. Without the right data, you're essentially driving blind, unable to prove the program’s value or spot where things could be better. This is where Key Performance Indicators (KPIs) come in, transforming your maintenance efforts from a line item on the budget into a measurable, strategic advantage.

Think of KPIs as the dashboard for your maintenance program. They give you a clear, at-a-glance view of your fleet's health, efficiency, and financial performance. By tracking these vital signs, you can catch trends early, make smarter decisions, and show stakeholders a real return on their investment.

Tracking Preventive Maintenance Compliance

One of the most foundational metrics to watch is your Preventive Maintenance Program Compliance (PPMC) rate. This KPI simply measures how consistently you’re getting scheduled maintenance done on time. It’s a direct reflection of how well you’re sticking to the plan.

A low compliance rate is a major red flag. It means vehicles are missing critical services, which dramatically increases the risk of an unexpected breakdown. A common industry benchmark for a well-run program is a PPMC rate of 90% or higher.

Calculating Your Cost Per Mile

The Cost Per Mile (CPM) is the ultimate financial scoreboard for your fleet. This KPI rolls up all your fleet-related expenses—fuel, maintenance, repairs, depreciation—into a single, powerful number. It tells you exactly how much it costs to operate each vehicle for every single mile it travels.

To figure it out, just divide your total fleet operating costs over a certain period by the total miles driven in that same period. If your CPM is consistently going down, that's a crystal-clear sign your preventive maintenance program is working, cutting down on expensive reactive repairs.

By diligently tracking CPM, you can pinpoint which vehicles are becoming too expensive to keep on the road and make data-backed decisions about when to repair versus when it's time to replace an asset.

Monitoring Vehicle Uptime Percentage

For any business that relies on its fleet, vehicle uptime is everything. This KPI measures the percentage of time your vehicles are available and ready to work versus sitting in the shop. High uptime means your assets are out on the road, doing their job and generating revenue.

The goal here is simple: maximize this number by minimizing unscheduled downtime. While a perfect 100% is pretty much impossible, top-performing fleets often hit uptime rates of 95% or higher. This shows that their preventive program is catching problems before they turn into major, lengthy repairs.

Understanding Mean Time Between Failures

Mean Time Between Failures (MTBF) tracks the average amount of time a vehicle operates successfully before it breaks down. A rising MTBF is a powerful indicator of your fleet's reliability and the effectiveness of your maintenance strategy. It proves your proactive work is paying off by extending the operational life between those disruptive failures.

This KPI is especially useful for spotting trends. If you see the MTBF for a specific vehicle model starting to drop, it could signal an underlying issue that needs a closer look, letting you adjust your maintenance schedule before it becomes a bigger problem. Real numbers paint a compelling picture; some AI-enhanced preventive approaches have been shown to yield 75% fewer breakdowns and 10-30% higher asset availability, positioning these programs as indispensable tools for driving efficiency. You can discover more insights about these fleet management market trends on gminsights.com.

Finding the Right Partner for Your Fleet

Rolling out a solid preventive maintenance program really comes down to one big decision: who do you trust with your vehicles? This isn’t about just finding any old repair shop. It's about finding a strategic partner who’s as invested in your fleet’s uptime and success as you are.

The right partner gets it—the name of the game is minimizing downtime. They should feel like an extension of your own team, working proactively to keep your vehicles on the road where they belong, making you money. For fleets in the Dallas area, that means you need someone who does a lot more than just change the oil.

What to Look for in a Fleet Service Provider

A top-notch partner brings a mix of expertise, convenience, and straight-up honesty to the table. They know that a mixed fleet of sedans, work trucks, and SUVs can't be treated with a one-size-fits-all approach; each vehicle has its own story and needs.

Here’s what you should be looking for:

- Tailored Programs: They should be able to build custom maintenance schedules that make sense for your specific vehicles, factoring in their age, how they’re used, and manufacturer recommendations.

- Flexible Hours: You need a shop that works around your schedule, not the other way around. Convenient hours are critical to getting vehicles serviced without disrupting your operations.

- Advanced Diagnostics: Modern vehicles require modern tools. A good partner invests in the latest diagnostic equipment to catch small issues before they turn into major, budget-busting failures.

- Transparent Pricing: No surprises. You need clear, upfront cost estimates so you can actually manage your maintenance budget without pulling your hair out.

Choosing a partner is about building a relationship based on trust and a shared commitment to maximizing your fleet's performance and safety.

At the end of the day, you want to team up with a provider who helps you get a handle on costs, stay compliant with regulations, and keep your vehicles on the move. You can see how Kwik Kar builds custom fleet services in Dallas to hit every one of these targets.

Answering Your Fleet Maintenance Questions

Even with a solid plan, questions are bound to pop up. Getting clear on the details of a fleet preventive maintenance program helps everyone on your team understand its value and get on the same page. Let’s tackle some of the most common questions fleet managers have.

How Often Should a Fleet Vehicle Get Preventive Maintenance?

There's no single magic number here. The right service interval really depends on the vehicle's job, its age, how it's used, and what the original manufacturer suggests. Think about it: a high-mileage delivery van navigating stop-and-go Dallas traffic will need a lot more love than an executive sedan that sees limited use.

The best approach is to build a flexible schedule that considers a few key factors:

- Mileage: Service is triggered after a certain number of miles are driven.

- Engine Hours: This is crucial for vehicles that spend a lot of time idling, like utility trucks or emergency vehicles.

- Time: Calendar-based checks (say, every six months) are important for things like fluid degradation and component aging, which happen even if the vehicle isn't moving.

A good rule of thumb is to service a vehicle based on whichever benchmark comes first—for example, every 5,000 miles or six months. Working with an experienced service partner can help you fine-tune these schedules for each specific vehicle in your fleet.

What Is the Difference Between Preventive and Predictive Maintenance?

People often mix these two up, but they’re really different philosophies for keeping vehicles on the road.

Preventive maintenance is all about the schedule. It's based on time or usage, involving routine services meant to prevent problems down the road. A classic example is changing the oil every 5,000 miles.

Predictive maintenance, on the other hand, is condition-based. It uses real-time data from telematics and sensors to predict when a specific part is likely to fail. This allows you to schedule a repair just before the breakdown happens.

While predictive tech is impressive, a strong preventive maintenance program is the bedrock of any successful fleet. Most top-performing fleets use a hybrid approach, starting with a solid preventive schedule and using data to flag potential issues early.

Can a Preventive Maintenance Program Really Save My Business Money?

Absolutely. It might seem like an upfront cost, but the long-term savings are huge and come from multiple directions. A well-run program slashes the number of expensive emergency repairs—the kind that often include towing fees, overtime for mechanics, and marked-up parts prices.

But it goes deeper than that. Well-tuned engines are more fuel-efficient. Proactive care extends the life of your vehicles, pushing back those huge replacement costs. And when it's time to sell, a vehicle with a solid service history has a much higher resale value.

Most importantly, it keeps your vehicles on the road and earning money. An asset sitting in the shop isn't generating revenue. That makes a proactive fleet preventive maintenance program a direct investment in your bottom line.

Ready to build a maintenance program that boosts uptime and cuts costs? The experts at Kwik Kar Oil Change and Auto Care create custom fleet service plans for businesses all over the Dallas area. Schedule your fleet consultation today!